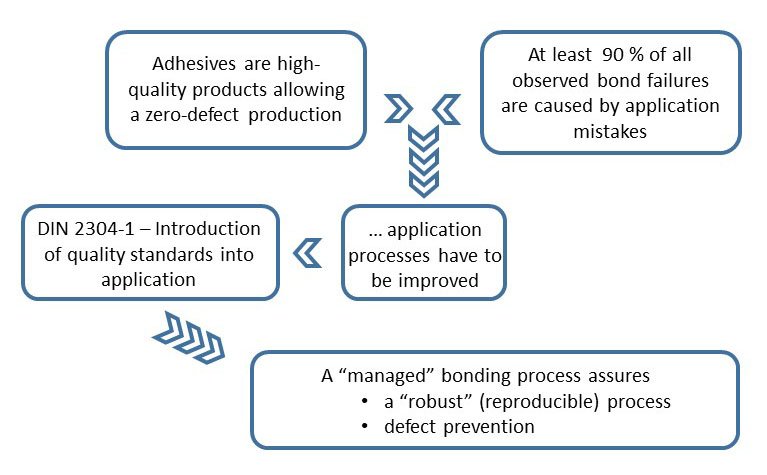

Bonding technology is undisputedly regarded as a key technology of the 21st century. There is hardly a branch of industry or trade in which it is not used innovatively. Germany is considered the world technology leader in this field. The adhesive manufacturers’ products intended for industrial use are high-quality products whose manufacturing processes are “mastered” processes in accordance with standards.

The professional use of these adhesives – from planning to the bonded product – usually leads to a zero-defect production in the application. However, this is contradicted by the fact that, unfortunately, too many adhesives do not meet the requirements placed on them and failures occur during use. From an objective point of view, about 90 % of the occurring bonding defects are due to a lack of knowledge about bonding technology. The DIN 2304-1 “Bonding Technology – Quality Requirements for Bonding Processes” takes up the contradiction between adhesives enabling zero-defect production on the one hand and preventing adhesive defects on the other: If the main reason for bonding defects is not adhesive defects, but application errors, then improvements must be made in the application area.